In today's activewear market, the selection of the right fabric is more critical than ever. As a professional supplier, founded in 2004, Haining Yitai Knitting Co., Ltd has grown into one of the high‑quality performance knitting fabric suppliers. We are dedicated to developing and manufacturing knitting fabric from the very beginning. After 15 years of development, we have built an excellent R&D group, marketing team, quality control system, experienced dyeing & finishing supporting facility and customer service system. Now instead of pursuing lower labour costs, higher output, and cheaper prices, we are more focusing on higher quality and better supporting service. In this guide, we explore how to choose and evaluate yoga fabrics so that your design, sourcing or production programmes stay ahead of market expectations.

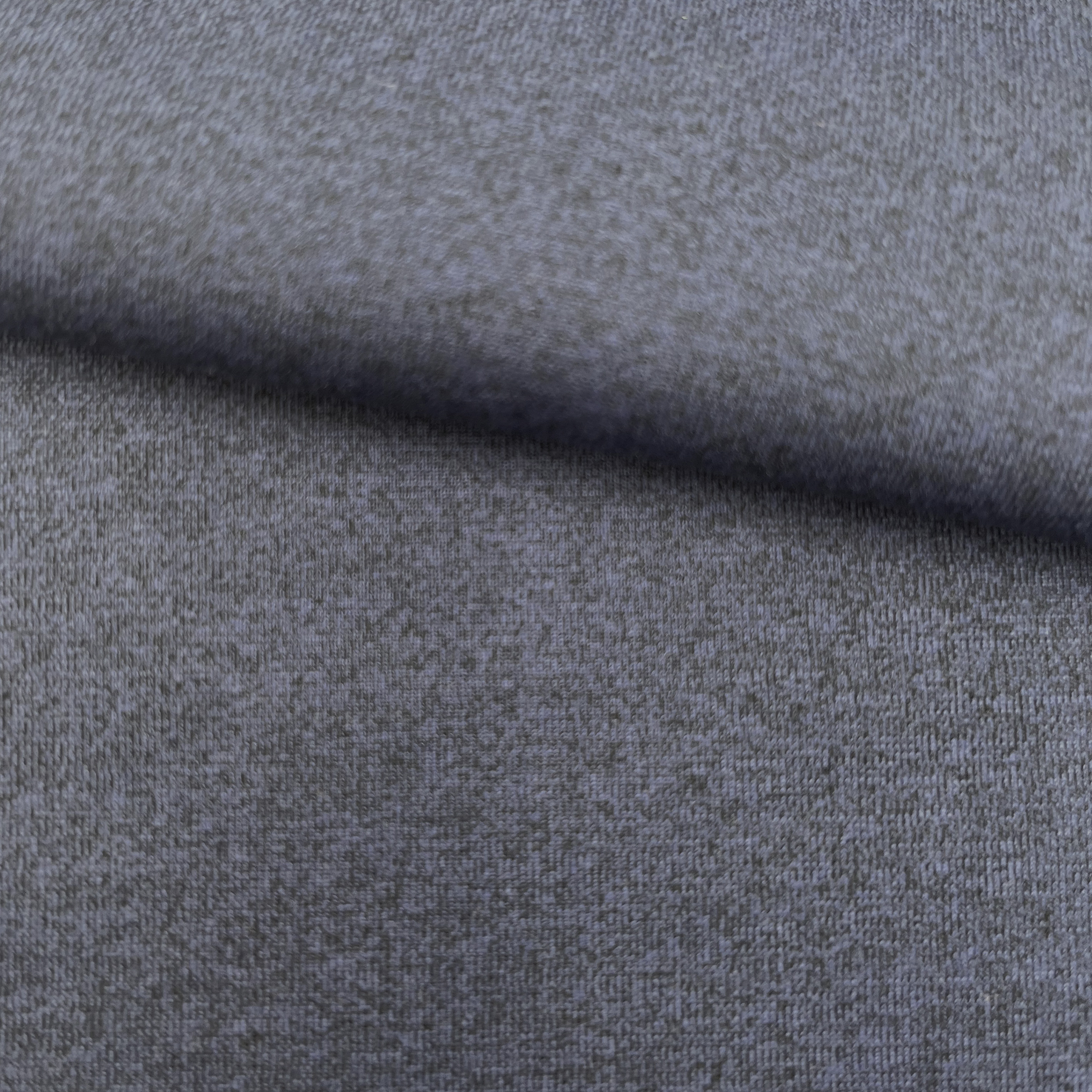

85% Cationic 15% Spandex, WEIGHT 280 GSM WIDTH 155CM Blue Black Single Jersey Fabric

1. Why Selecting the Right yoga fabrics Matters

1.1 Comfort and flexibility demands in yoga wear

- Yoga wear must allow full range of motion — bends, stretches, lunges.

- Inappropriate fabric can restrict movement, pinch, or lose shape.

- High‑performance yoga design demands fabrics that feel like a "second skin".

1.2 How fabric choice affects performance, durability and feel

- A fabric with poor stretch recovery may sag after a few uses.

- Moisture‑trapping fabrics can become heavy, clingy and uncomfortable.

- Durable fabrics extend garment life — reducing replacements and enhancing brand reputation.

2. Key Performance Features of Yoga Fabrics

2.1 Stretch and recovery – what to look for

- Four‑way stretch knits are preferred for dynamic yoga flows.

- High recovery means fabric returns to original shape after use.

- Low recovery leads to "bagging" and poor fit over time.

2.2 Moisture‑management and breathability

- "moisture‑wicking yoga fabrics for hot yoga" are essential for intense classes.

- Breathable fabrics help regulate body temperature and comfort.

- Synthetic fibres like nylon or polyester blends excel in wicking performance.

2.3 Durability and wear‑resistance for frequent use

- Studio garments undergo frequent washing — durability matters.

- High‑tenacity yarns and tight knits resist pilling and fading.

- Choosing the right weight (gsm) contributes to longevity and structure.

3. Comparing Fabric Types for Yoga Applications

3.1 Natural vs synthetic fibre blends

- Natural fibres (e.g., cotton, bamboo) offer softness and breathability.

- Synthetic blends (e.g., polyester/spandex, nylon/spandex) offer higher performance in stretch and recovery.

- Each has trade‑offs: cotton absorbs sweat, synthetics may feel less "natural".

3.2 Knit construction types suitable for yoga fabrics

- Interlock knit: good structure, stable and suitable for bottoms.

- Single jersey: lighter weight, good for tops and layering.

- Rib knit: useful for waistbands, cuffs with high recovery.

3.3 Comparison table: which fabric suits which use case

| Use Case |

Recommended Fabric Blend |

Key Benefit |

| Hot yoga / high intensity |

70 – 85% nylon + 15 – 30% spandex |

Excellent sweat‑management & shape retention |

| Restorative / casual yoga |

Natural fibre (e.g., cotton or bamboo) + spandex 5‑10% |

Soft feel, breathable, ideal for low‑impact |

| Studio performance leggings |

Polyester/spandex or recycled nylon blend |

Durable, colourfast, high stretch recovery |

4. How to Choose the Right Yoga Fabric Supplier

4.1 Evaluating manufacturing, R&D and quality control capability

- Look for suppliers with dedicated R&D teams and experience in performance fabrics.

- Quality control systems ensure shrinkage, colour‑fastness, and stretch recovery are maintained.

- Our company (Haining Yitai) emphasises "intelligence creation and high quality" from early days.

4.2 Ensuring support for customisation, finishing and customer service

- Check supplier offers dyeing, finishing, fabric treatments (e.g., antimicrobial, moisture‑wicking finishes).

- Good customer service and communication help meet lead‑times and specifications.

- We continually improve service to customers and focus on better supporting service.

4.3 Practical checklist when sourcing "eco‑friendly yoga fabrics knit supplier" or other special requirements

- Ask for certifications (e.g., OEKO‑TEX, GOTS) if sustainability is key.

- Request fabric swatches, test for stretch, recovery, wash performance.

- Consider logistics, repeat‑order capability, minimum quantities, lead‑time.

5. Best Practices for Selecting and Using Yoga Fabrics

5.1 Matching fabric choice to yoga style

- For hot yoga: prioritise **moisture‑wicking**, quick‑dry fabrics.

- For power yoga: focus on **high‑stretch** and recovery to support transitions.

- For restorative or lounge‑style yoga: softer, comfortable fabrics suffice.

5.2 Care instructions and maintenance for longevity

- Wash in cold water, use gentle cycle to preserve elasticity.

- Avoid fabric softeners which may reduce moisture‑wicking properties.

- Air‑dry when possible to maintain shape and avoid heat damage.

5.3 Case scenario: "moisture‑wicking yoga fabrics for hot yoga" vs "durable yoga fabrics for studio garments"

- If your brand focuses on studio classes where garments are washed daily, choose fabrics engineered for durability (e.g., high‑tenacity nylon/spandex blends).

- Supplier capability must align: fabric weight, treatment, and finishing will differ by scenario.

6. Summary and Outlook for Yoga Fabrics Market

6.1 Recap of what to prioritise

- Comfort, stretch, recovery, moisture‑management, durability.

- Match fabric properties to your end‑use scenario.

- Partner with a supplier who understands performance fabrics and offers quality service — as our company has done since 2004.

6.2 Future trends: high‑stretch yoga fabrics for performance wear, sustainability and customisation

- Increasing demand for eco‑friendly or recycled fibre blends.

- Greater emphasis on performance finishing (antimicrobial, UV‑protection).

- Custom colour, knit and finishing options giving brands differentiation.

FAQ

- Q1: What fabric blend is best for hot yoga leggings?

A: Look for a blend such as ~70‑85% nylon + 15‑30% spandex that offers strong moisture‑wicking, fast‑drying and excellent stretch recovery.

- Q2: Can natural fibres like cotton work for yoga garments?

A: Yes — for low‑intensity or restorative yoga, cotton or bamboo blends provide softness and breathability; however they absorb moisture and are slower to dry compared with synthetics.

- Q3: What should I check when sourcing an eco‑friendly yoga fabrics knit supplier?

A: Verify certifications, ask for fabric treatments, examine knit structure, check finishing and support services, request test reports and swatches.

- Q4: How do I care for high‑performance yoga fabrics to extend their life?

A: Wash in cold water, avoid fabric softener, air‑dry or tumble low, avoid high heat and rough surfaces to preserve stretch and finish.

- Q5: Why are some yoga fabrics more expensive even if they look similar?

A: Because performance fabrics often use high‑tenacity fibres, specialised finishings (e.g., moisture‑wicking, antimicrobial), higher quality knit structures and stricter QC — all adding cost. Choosing "affordable yoga fabrics for activewear" requires balancing cost with required performance.