Why Fabric Defines Athletic Performance

In the world of sports and fitness, cloth material for sportswear is far more than just a covering. It is a critical component that can significantly influence an athlete's comfort, endurance, and overall performance. Unlike everyday apparel, sportswear fabrics are engineered with specific functional demands in mind.

Beyond Regular Clothing: How Materials Elevate Performance

- Thermal Regulation: During intense physical activity, the body generates considerable heat. Advanced sportswear fabrics are designed to manage this heat, preventing overheating in warm conditions and offering insulation in cold environments, ensuring optimal body temperature.

- Dynamic Support: High-performance materials provide targeted compression and flexibility. This supports muscle groups, reduces vibration, and allows for an unrestricted range of motion, crucial for activities from weightlifting to sprinting.

- Moisture Management: Sweat is a natural physiological response to exertion. The right fabric actively wicks sweat away from the skin, preventing chafing, discomfort, and the chilling effect of evaporating moisture.

The Three Core Missions of Modern Sportswear Fabrics

Every fiber, weave, and finish in contemporary sportswear is meticulously chosen to fulfill a triad of essential functions:

- Protection: This extends beyond simple physical barriers. It includes protection from the elements (wind, rain, UV radiation), abrasion during falls or contact sports, and even microbial growth that causes odor.

- Comfort: An athlete should feel unhindered and focused. Comfort in sportswear is derived from the fabric's soft hand-feel, lightweight nature, breathability, and seamless construction that prevents chafing.

- Enhancement: This is where fabric innovation truly shines. Features like graduated compression, aerodynamic textures, and responsive stretch patterns directly contribute to improving an athlete's biomechanics and reducing fatigue, thereby enhancing performance.

The Evolution of Sportswear Material Science

From simple cotton uniforms to today's sophisticated multi-fiber composites, sportswear material science has undergone a dramatic transformation. This evolution is driven by:

- Fiber Innovation: The development of synthetic fibers like polyester and nylon, and the refinement of natural fibers like merino wool for performance applications.

- Weaving Technology: Advanced knitting and weaving techniques that create specific textures for breathability, durability, and aerodynamic properties.

- Chemical Treatments: Coatings and finishes that add water repellency, UV protection, or antimicrobial properties without compromising breathability.

The Foundations of Sportswear: Core Fiber Categories

The performance of any cloth material for sportswear begins at the molecular level. Fibers are generally categorized into high-performance synthetics and comfort-oriented natural or semi-synthetic blends, each offering unique advantages for the athlete.

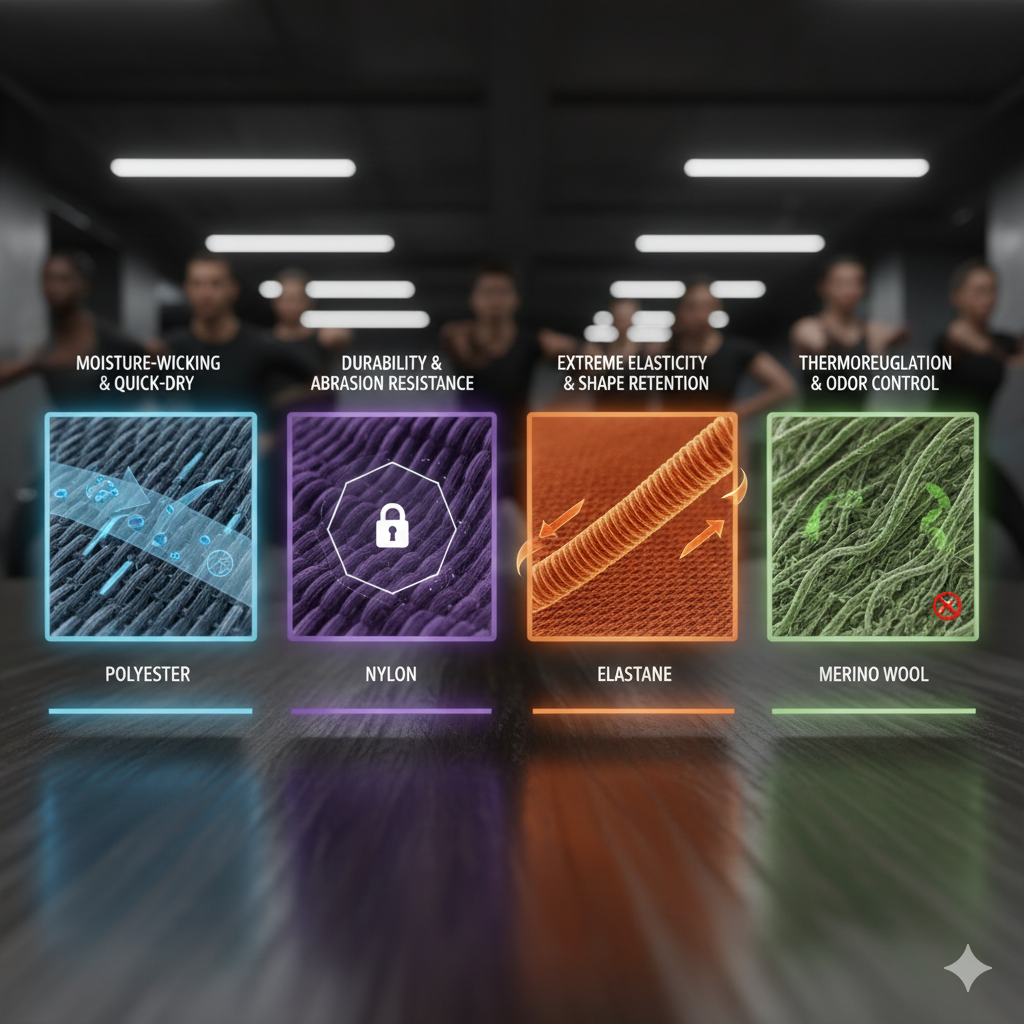

1. Synthetic Fibers: The Performance Powerhouses

Synthetic fibers dominate the athletic market due to their engineering flexibility. They can be manipulated to be incredibly strong, stretchy, or water-repellent.

- Polyester: The backbone of the industry. It is highly durable, resistant to shrinking and stretching, and most importantly, hydrophobic. It doesn't absorb much moisture, allowing sweat to evaporate quickly.

- Nylon (Polyamide): Known for its superior strength and abrasion resistance. Nylon is often used in garments that face high friction, like cycling shorts or windbreakers, and it offers a smoother, silkier feel than polyester.

- Elastane (Spandex/Lycra): This fiber provides the "soul" of athletic movement. With the ability to stretch over 500% of its length and return to its original shape, it is essential for tight-fitting gear and unrestricted range of motion.

2. Natural & Semi-Synthetic Fibers: The Comfort Choice

While synthetics lead in durability, natural and bio-based fibers are regaining popularity for their superior skin-feel and eco-friendly profiles.

- Merino Wool: A miracle fiber from nature. It is naturally temperature-regulating (warm in winter, cool in summer) and possesses inherent antimicrobial properties that prevent odors from building up.

- Lyocell (Tencel): A semi-synthetic fiber derived from wood pulp. It is more absorbent than cotton, softer than silk, and cooler than linen, making it an excellent choice for low-to-medium intensity activities.

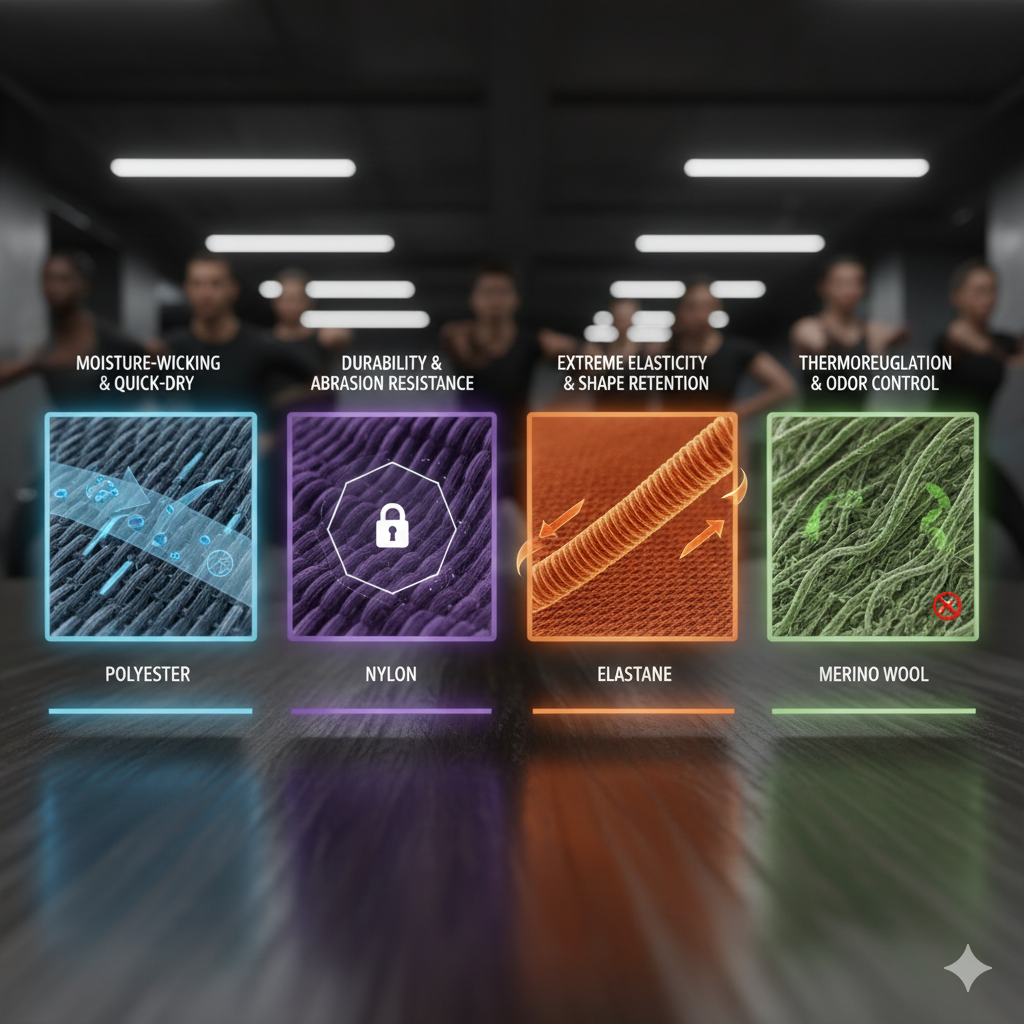

Fiber Comparison Table

| Fiber Type |

Primary Strength |

Common Application |

| Polyester |

Moisture-wicking & Quick-dry |

Running shirts, Team jerseys |

| Nylon |

Durability & Abrasion resistance |

Compression tights, Outerwear |

| Elastane |

Extreme Elasticity |

Yoga pants, Swimwear |

| Merino Wool |

Odor control & Thermoregulation |

Base layers, Outdoor socks |

Key Performance Metrics of Sportswear Fabrics

The effectiveness of cloth material for sportswear is measured by specific scientific metrics. These performance indicators determine how a garment will behave under the stress of high-intensity movement and varying environmental conditions.

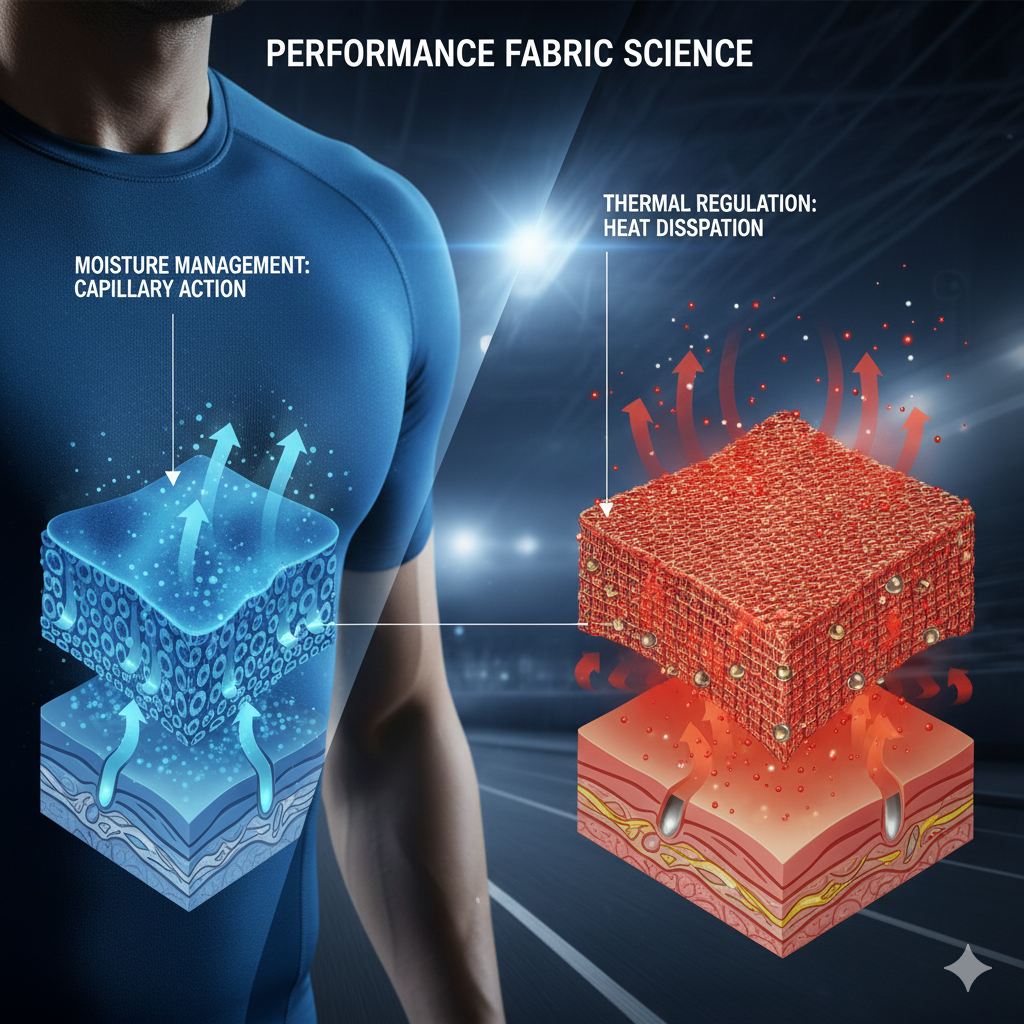

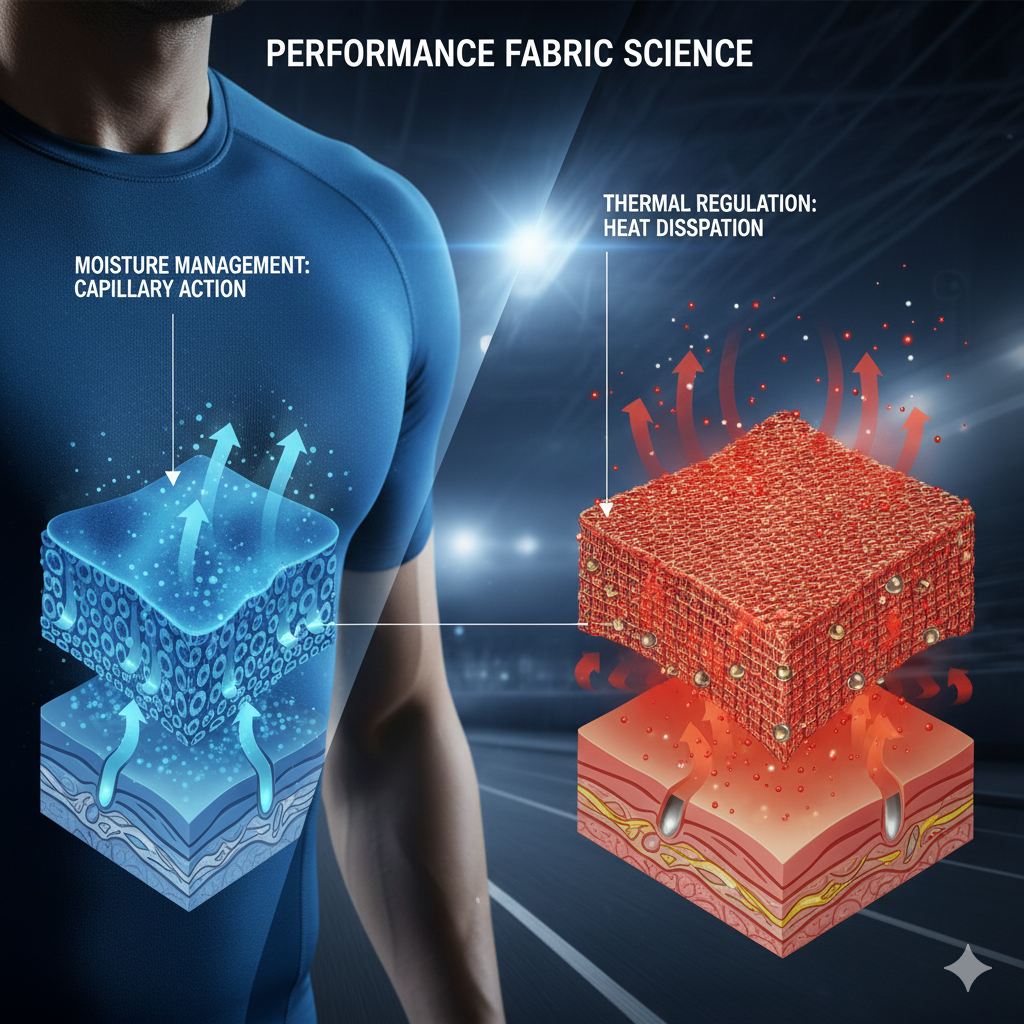

1. Thermoregulation: Managing the Heat

The body’s efficiency drops significantly if it cannot dissipate heat. Performance fabrics utilize breathability and heat-conductive properties to regulate the microclimate between the skin and the garment.

- Vapor Permeability: The fabric's ability to allow warm air and sweat vapor to escape through the knit structure.

- Thermal Conductivity: Some advanced fabrics incorporate minerals or metallic elements (like ceramic or graphene) to help pull heat away from the body faster.

2. Moisture Management: The Wicking Process

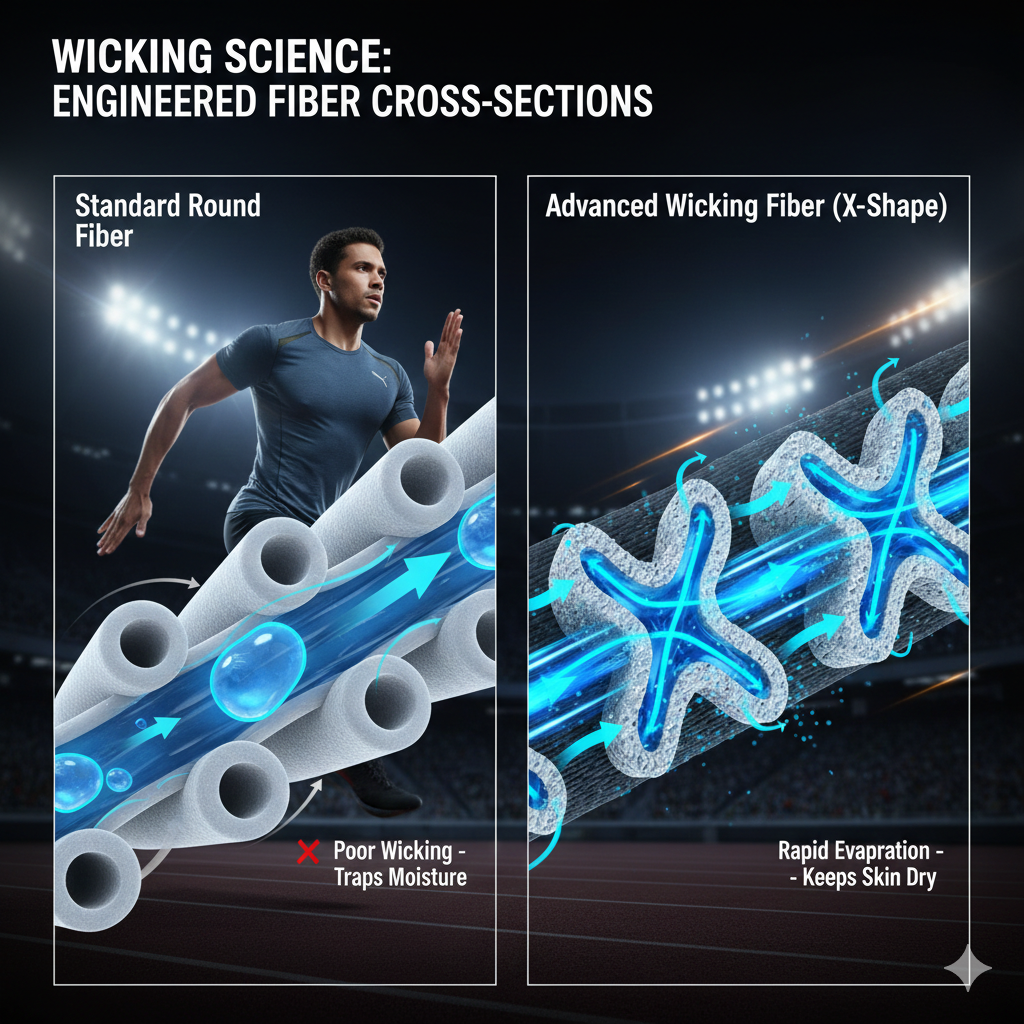

Modern sportswear relies on capillary action to manage sweat. This is the movement of liquid across a fabric’s surface and through its thickness.

- Wicking: Fibers are engineered with non-round cross-sections (like "X" or "Y" shapes) that create channels to pull sweat from the skin to the outer layer.

- Evaporation Rate: High-performance polyester allows moisture to spread across a large surface area on the outside of the cloth, leading to rapid drying.

3. Compression and Aerodynamics

For many athletes, the fabric’s physical interaction with air and muscle is a game-changer.

- Muscle Support: High-elastane blends provide compression, which reduces muscle oscillation (vibration) and can help delay fatigue during long-duration sports.

- Drag Reduction: In sports like cycling or speed skating, "dimpled" or textured fabric surfaces are used to manage airflow and reduce aerodynamic drag.

Performance Metrics Summary

| Metric |

How it Works |

Athlete Benefit |

| Breathability |

Airflow through porous fibers |

Prevents overheating and core temp spikes. |

| Capillary Action |

Liquid transport via fiber channels |

Keeps skin dry and prevents chafing. |

| Elastic Recovery |

Ability to snap back to original shape |

Ensures consistent fit and muscle support. |

| UPF Rating |

UV radiation blockage |

Protects skin during long outdoor sessions. |

Selecting Sportswear Fabrics for Specific Activities

Choosing the right cloth material for sportswear requires matching the fabric's properties to the unique demands of the sport. A fabric that excels in a yoga studio may fail on a mountain trail or a marathon track.

1. HIIT & Gym Training: Durability and High Compression

High-Intensity Interval Training involves explosive movements, heavy lifting, and significant friction against equipment. The priority here is mechanical strength and muscle stabilization.

- Ideal Choice: Heavy-weight Nylon-Spandex blends.

- Why: Nylon provides the abrasion resistance needed for barbell contact, while high Spandex content (above 15%) offers the compression necessary to reduce muscle vibration during plyometrics.

2. Long Distance Running: Lightweight and Anti-Chafe

For runners, every gram of weight matters, and repetitive motion makes skin irritation a major risk. Fabrics must be ultra-light and exceptionally smooth.

- Ideal Choice: 100% Lightweight Polyester or Micro-Fiber blends.

- Why: These materials minimize water retention from sweat, keeping the garment light. Laser-cut edges and bonded seams are often used to eliminate friction points.

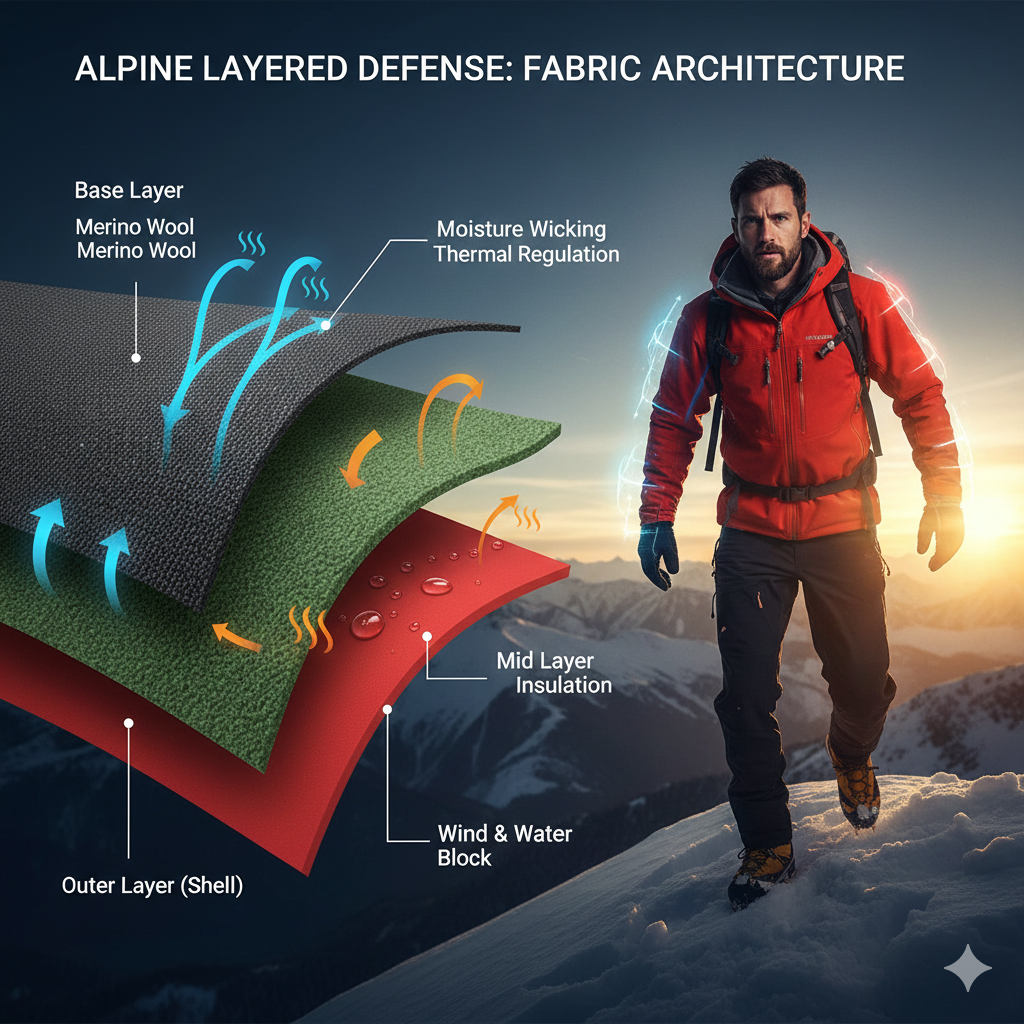

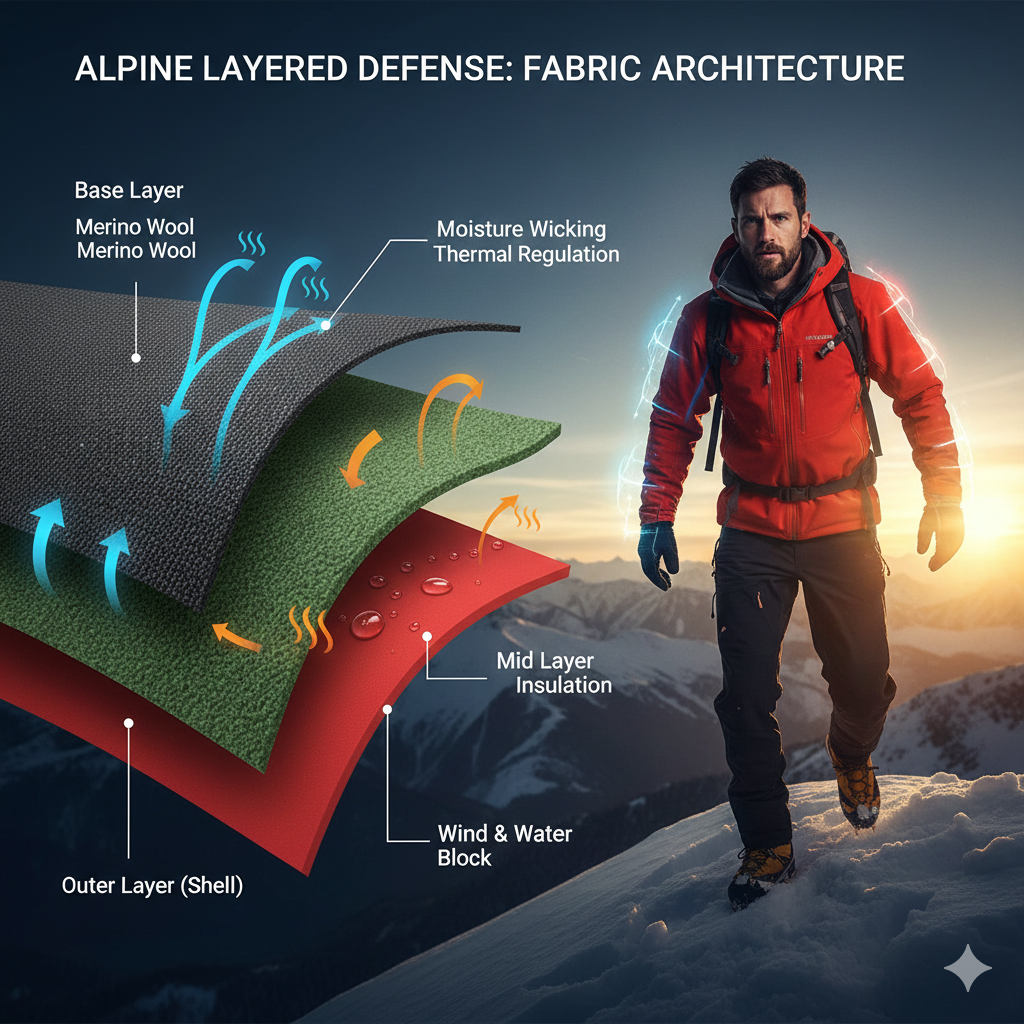

3. Outdoor & Alpine Sports: The Layering System

Outdoor exploration requires protection from external elements like wind and rain while managing internal moisture. This is achieved through Multi-layer Architecture.

- Base Layer: Merino Wool or Synthetic silk for moisture wicking.

- Mid Layer: Fleece (brushed polyester) for thermal insulation.

- Outer Layer (Shell): Hard-shell fabrics with a DWR (Durable Water Repellent) coating to block wind and water.

Activity-Based Fabric Matrix

| Activity |

Critical Feature |

Recommended Fabric |

| HIIT / Crossfit |

Abrasion resistance & Support |

Nylon + High Spandex |

| Marathon / Running |

Zero-distraction & Fast-dry |

Micro-polyester / Single jersey |

| Cycling |

Aerodynamics & Comfort |

Warp-knit Nylon + Chamois padding |

| Swimming / Surf |

Chlorine resistance & UPF |

PBT (Polybutylene Terephthalate) |

Advanced Weaving and Coating Technologies

The performance of a cloth material for sportswear is determined not just by the fibers used, but by how they are structured and treated. Advanced engineering at the textile level allows for targeted functionality that traditional fabrics cannot match.

1. Seamless Knitting: Frictionless Freedom

Traditional sportswear is often constructed from flat panels sewn together, creating bulky seams. Seamless technology uses circular knitting machines to create an almost finished garment in a single piece.

- Reduced Chafing: By eliminating seams in high-friction areas (like the underarms and inner thighs), the risk of skin irritation during long workouts is nearly eliminated.

- Zoned Functionality: Different knit patterns can be integrated into one piece—tighter weaves for support and looser, mesh-like weaves for ventilation—without extra stitching.

2. DWR (Durable Water Repellent) Coatings

For outdoor athletes, maintaining breathability while staying dry is a paradox solved by DWR coatings. This is a chemical treatment applied to the fabric surface.

- The Lotus Effect: The coating creates microscopic "spikes" that increase surface tension, causing water to bead up and roll off rather than soaking into the fibers.

- Breathability Maintenance: Unlike a plastic raincoat, DWR doesn't block the pores of the fabric, allowing sweat vapor to still escape from the inside.

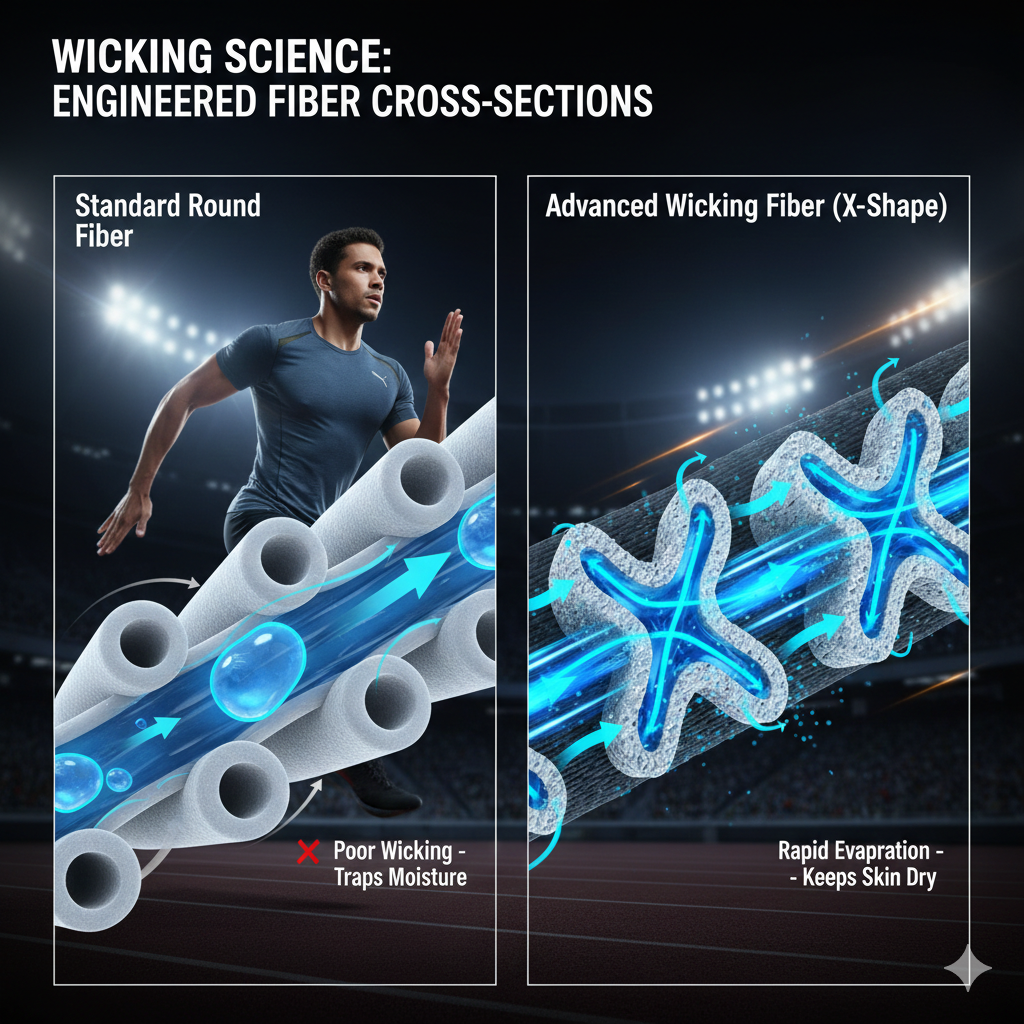

3. Engineered Fiber Cross-Sections (Dri-FIT Technology)

High-performance fabrics like Dri-FIT or Coolmax aren't just chemically treated; they are physically reshaped. Instead of round fibers, they use "X" or "Y" shaped cross-sections.

- Increased Surface Area: These shapes provide more space for moisture to travel.

- Accelerated Evaporation: By pulling moisture to the outer surface of the garment and spreading it out, the fabric allows air to dry the sweat much faster than standard cotton or round-fiber synthetics.

Fabric Construction Comparison

| Technology |

Mechanism |

Core Benefit |

| Seamless Knit |

Continuous circular loom |

Maximum comfort & aesthetic "sculpting." |

| DWR Coating |

Molecular surface hydrophobic barrier |

Water resistance without losing breathability. |

| Engineered Cross-Section |

Non-round fiber extrusion |

Superior moisture transport (wicking). |

| Jacquard Mesh |

Integrated hole patterns in the weave |

Targeted cooling in high-heat zones. |

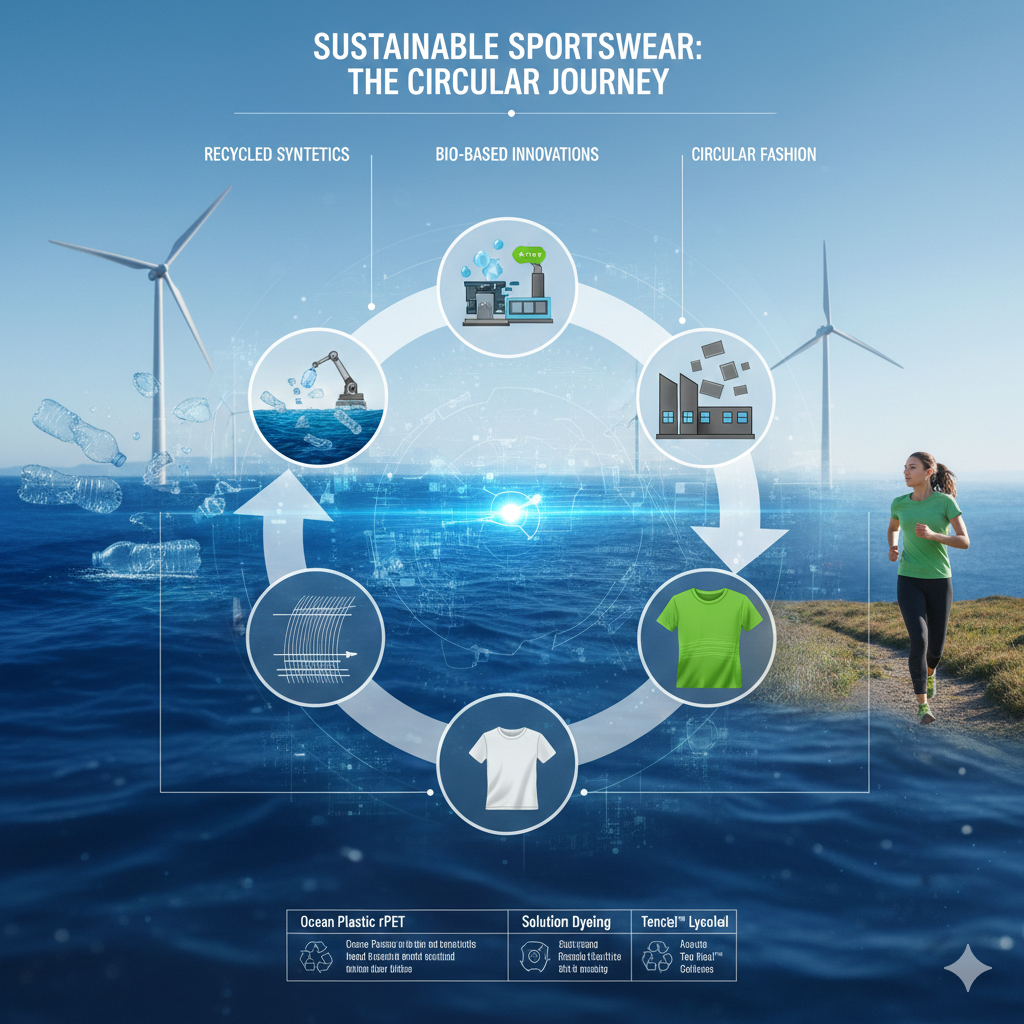

Sustainability in Sportswear Fabrics

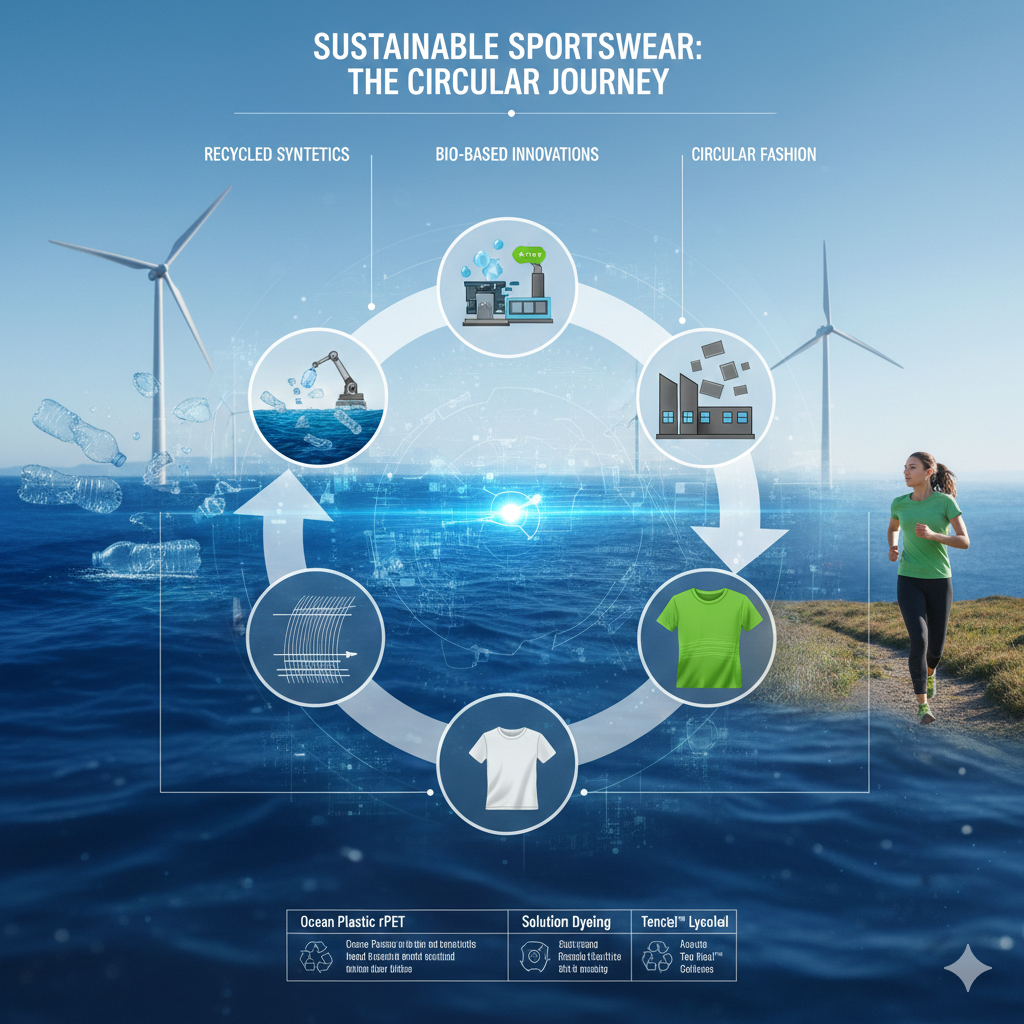

As the global awareness of environmental impact grows, the cloth material for sportswear industry is undergoing a "green revolution." Innovations are now focused on maintaining high performance while drastically reducing the ecological footprint of athletic apparel.

1. Recycled Synthetics: Turning Waste into Performance

The most significant shift has been the move from virgin petroleum-based polyester to recycled alternatives.

- rPET (Recycled Polyester): Made primarily from post-consumer plastic bottles and intercepted ocean plastic. It offers the same durability and moisture-wicking properties as virgin polyester but uses 30-50% less energy to produce.

- Recycled Nylon: Sourced from discarded fishing nets, fabric scraps, and industrial plastic. It helps divert waste from landfills while providing the high-tenacity support required for compression gear.

2. Bio-Based and Biodegradable Innovations

The future of sportswear lies in materials that can return to the earth without leaving a trace of microplastics.

- Bio-based Polyamide: Synthetic fibers derived from castor oil or other plant sources rather than fossil fuels.

- Biodegradable Elastane: Traditional spandex can take centuries to decompose. New lab-engineered stretch fibers are being developed to break down in landfill conditions within a few years.

3. Circular Fashion: Designing for the End-of-Life

True sustainability means moving away from a "take-make-waste" model toward a circular economy.

- Monomaterial Construction: Designing a garment (including zippers and threads) from a single fiber type to make it 100% recyclable.

- Solution Dyeing: A process where color is added to the liquid polymer before the fiber is spun, saving thousands of liters of water and reducing chemical runoff compared to traditional vat dyeing.

Sustainability Impact Table

| Eco-Innovation |

Environmental Saving |

Performance Integrity |

| Ocean Plastic rPET |

Reduces marine pollution & CO2 |

Identical to virgin polyester. |

| Solution Dyeing |

Up to 90% less water usage |

Higher color fastness & UV resistance. |

| Tencel™ Lyocell |

Closed-loop solvent system |

Exceptional moisture absorption. |

Maintenance and Care for Sportswear Fabrics

Even the most advanced cloth material for sportswear can lose its functional properties if not maintained correctly. High-performance fibers are delicate and require specific care to preserve their elasticity, breathability, and technical coatings.

1. The Science of Washing Performance Gear

Standard laundry detergents and high heat are often the enemies of technical textiles. To extend the life of your gear, follow these rules:

- Avoid Fabric Softeners: As discussed previously, softeners leave a waxy residue that clogs fiber channels, destroying the fabric's ability to wick sweat.

- Wash in Cold Water: High temperatures can break down elastane fibers, leading to sagging and loss of compression over time.

- Turn Garments Inside Out: This protects the outer finish (and any reflective logos or DWR coatings) from abrasion against the washing machine drum.

2. Drying and Odor Management

How you dry your sportswear is just as important as how you wash it.

- Air Dry Whenever Possible: The intense heat of a dryer can "cook" synthetic fibers, making them brittle and reducing their stretch recovery.

- Combatting "Permastink": Synthetic fibers like polyester are lipophilic (oil-loving), meaning they trap body oils and bacteria. If odors persist, use a specialized sports wash or a soak in white vinegar to break down the buildup.

3. Restoring Technical Features

Some features, like DWR (Durable Water Repellent), aren't permanent but can be revived.

- Reactivating DWR: If water stops beading on your rain jacket, a short tumble on low heat (after washing) can sometimes realign the hydrophobic molecules. If that fails, a "wash-in" or "spray-on" DWR treatment can be reapplied.

Summary Care Guide

| Common Mistake |

Impact on Fabric |

Correct Action |

| Using Fabric Softener |

Clogs wicking channels |

Use mild, liquid detergent only. |

| High-Heat Drying |

Damages Elastane/Spandex |

Line dry in the shade. |

| Bleaching |

Weakens Nylon/Polyester fibers |

Use oxygen-based cleaners if needed. |

| Washing with Velcro/Zippers |

Causes pilling and snags |

Use a mesh laundry bag. |