For underwear brands, how important is the washability of Underwear Poly Fabrics to maintaining brand image and product quality? How to ensure the stable performance of this feature during the production process?

For underwear brands, the washability of Underwear Poly Fabrics is of vital importance to maintaining brand image and product quality. The following will explore its importance in detail from various aspects and discuss how to ensure the stable performance of this characteristic during the production process.

First of all, washability is one of the important indicators of underwear quality. Underwear, as clothing worn next to the body, needs to be cleaned frequently, so its fabric must be able to withstand multiple washings without being prone to wear, deformation or fading. If underwear has poor washability, consumers may find that the underwear deforms, pills, or fades after multiple washes, which will seriously affect their trust and satisfaction with the brand. Therefore, underwear brands must ensure that the Poly Fabrics used have excellent washability to maintain brand image and product quality.

Secondly, washability is also related to the life and practicality of underwear. A piece of washable underwear can still maintain good appearance and performance after multiple washings, extending its service life and providing consumers with a better wearing experience. On the contrary, if the underwear is not washable, consumers may need to change underwear frequently, which not only increases their purchase costs, but may also cause inconvenience to their daily lives. Therefore, underwear brands can enhance the practicality and competitiveness of their products by improving the washability of Poly Fabrics.

In order to ensure that Underwear Poly Fabrics have stable washability performance during the production process, underwear brands can take the following measures:

Strictly screen fabric suppliers: Choose suppliers with good reputation and mature technology to ensure that the purchased Poly Fabrics meet the brand's requirements for washability.

Optimize the production process: Improve the washability of the fabric by improving the production process, such as using advanced dyeing and finishing technology. At the same time, we strengthen quality control during the production process to ensure that every process meets standards.

Conduct wash resistance testing: During the production process, Poly Fabrics are regularly tested for wash resistance to ensure stable performance. The test can include indicators such as the number of washes, degree of fading, degree of deformation, etc. to comprehensively evaluate the washability of the fabric.

Strengthen employee training: Improve employees’ awareness of the importance of washability so that they can pay more attention to this characteristic during the production process. At the same time, relevant skills and knowledge training are provided to employees to help them better master the techniques and methods for improving the washability of fabrics.

The washability of

Underwear Poly Fabrics is of great significance to underwear brands in maintaining their brand image and product quality. By strictly screening suppliers, optimizing production processes, conducting washability tests and strengthening employee training, underwear brands can ensure that Poly Fabrics have stable washability performance during the production process, thereby providing consumers with high-quality, durable products. Underwear products.

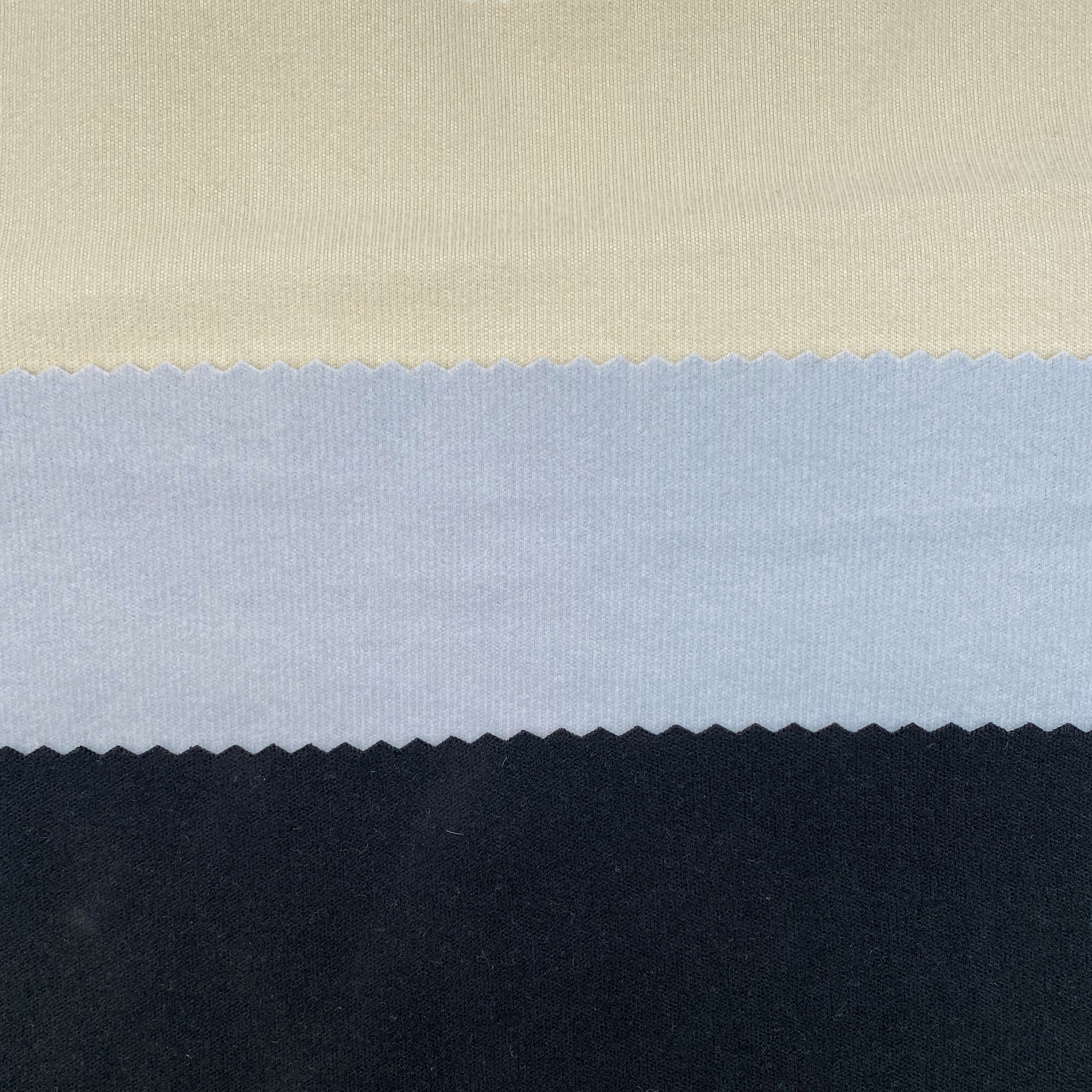

THERMAL UNDERWEAR FABRIC

THERMAL UNDERWEAR FABRIC